Steps to Prevent Accidental Injury from Moving MachineryĪnyone responsible for using a given piece of machinery must be fully trained on that machine’s LOTO protocols. Failure to test the machinery could result in grievous injury if the LOTO steps weren’t executed perfectly. This is one of the most overlooked steps in LOTO protocol, and it’s one of the most crucial. Test the Equipmentīefore conducting the scheduled maintenance, repair, or cleaning, make sure to test the machine to be certain the energy has been isolated. This is generally accomplished through grounding or blocking the energy. This may include locking or tagging out the ignition and other devices on the equipment that are responsible for isolating energy.Īny stored energy should be released or restrained before servicing the apparatus. Use all appropriate lockout, tagout, or alternative measures identified for the specific machinery you are working on. Manage the Energy SourceĬontrol any potentially hazardous energy by shutting off all the energy to the machine. This might include parking the machine, turning off the ignition, and disconnecting the power source. Use normal shut down procedures to turn off the equipment. Keeping everyone at the job site on the same page is one of the most important safety steps out there because it lowers the risk of accidents occurring as a result of ignorance or lack of information about a given situation. LOTO protocols should be properly explained to every worker who might operate the apparatus over the course of the work day. Make sure everyone who uses the machinery knows that you’re going to turn it off for maintenance. Your first step before initiating Lockout Tagout procedures should be to inform your fellow workers that you’re about to shut the equipment down. Specific LOTO protocols will vary depending on the type of machine involved. Here is a list of steps to be taken before conducting any repairs, maintenance, or cleaning of a piece of equipment. Lockout Tagout Checklist for a Maintenance or Repair Operation

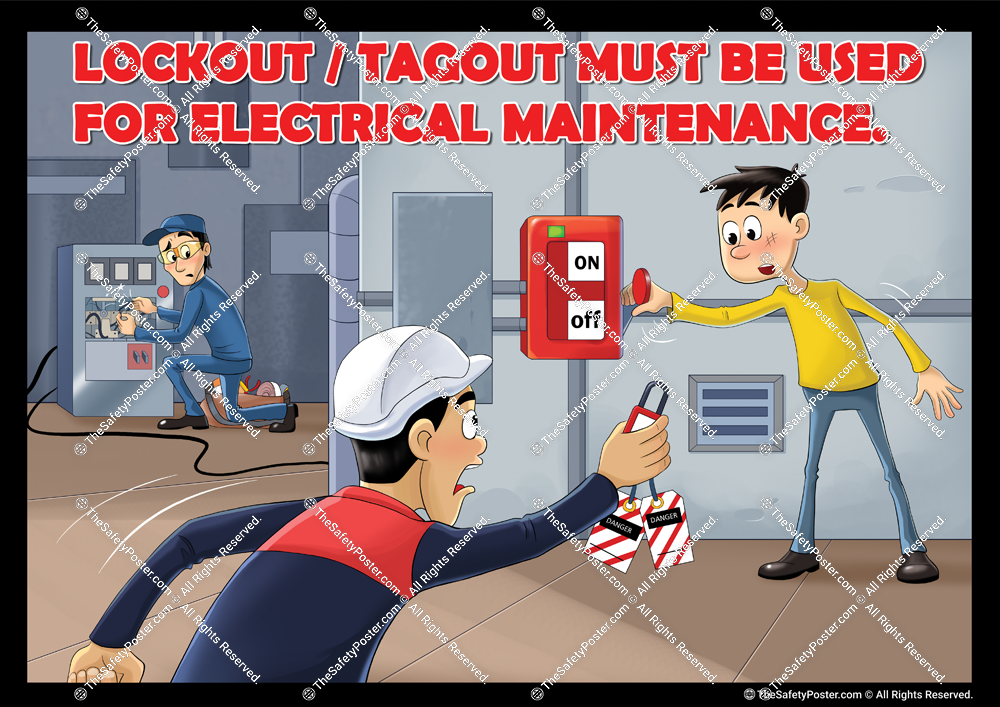

Even a quick or minor repair necessitates proper lockout protocols. Lockout Tagout needs to be executed before any and all maintenance, cleaning, or repair work is done on any moving equipment on the job site. Providing your employees with training on this important topic should be a cornerstone of your safety training program.

One keep component of understanding your training needs, is to understand exactly when lockout tagout is required.

LOTO also ensures that everyone working at a job site is on the same page about what’s going on with a given piece of equipment. Failure to perform LOTO can result in electrocutions, amputations, other critical injuries, or even death. LOTO guidelines exist to protect employees on a job site from serious harm due to moving equipment suddenly turning on during servicing. We do have a step-by-step lockout tagout procedure article that you should check out as well. The technician working on the apparatus must be in control at all times, which includes regulating the flow of hazardous energy by fully shutting down every source that powers the machine. When it comes to LOTO safety, control is the name of the game. Lockout Tagout (LOTO) is performed to negate the risk of an accidental release during the servicing, which could potentially result in serious injury or even death. “Locking” or “tagging” procedures refer to the steps employees must take to completely shut off a machine’s energy source before conducting any cleaning, repairs, or maintenance work. What Are Lockout Tagout Safety Procedures? Moving Equipment Requires Strict Safety Procedures.Steps to Prevent Accidental Injury from Moving Machinery.Lockout Tagout Checklist for a Maintenance or Repair Operation.

0 kommentar(er)

0 kommentar(er)